A farmer’s work is a never-ending cycle. Once the seeding season is over, the spraying stage must immediately begin. For several years now, self-propelled sprayers have been very popular in the agricultural world for the autonomy they offer and also for the precision of the products applied to every section of the field. We know that the window of application of pesticides and fertilizers is extremely narrow, hence the S-TECH 7016 track system has been specifically developed to optimize this limited working time.

Discover 5 reasons to use the S-TECH 7016 on your self-propelled sprayers:

- Get an improved spray coverage

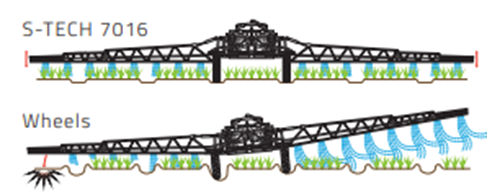

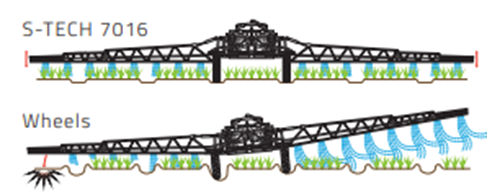

The S-TECH 7016 track system minimizes tire rebound and therefore significantly reduces ground pressure. These factors greatly improve boom stability and allow the boom to be lowered closer to the crop to provide ideal spray coverage with reduced drift.

- Reduce time loss

The larger ground contact area of the S-TECH 7016 makes it possible to load tanks to their full capacity. This maximizes your productivity by eliminating all unnecessary trips throughout the day.

- Spray when you need to spray

With the short application window, we do not want to be impacted by unpredictable weather, especially during the spring when the rain is often forecasted. Soucy track systems provide all the traction and flotation needed to work when soggy field conditions would prevent traditional wheels from getting the job done.

- Move between your rows without damaging your crops

The S-TECH 7016 has a very narrow track width of 406mm (16"), which makes driving between rows even easier and more precise. The track system also increases the ground clearance of the self-propelled sprayer by 152 mm (6 in’’), compared to traditional tires, for confident driving without damaging the plants.

- Eliminate daily maintenance

The S-TECH 7016 requires no daily maintenance. Oil bath hubs should be maintained annually or every 250 hours of usage. The design of this track system allows for easy cleaning allowing you to spend more time in the field.

Find out more about this track system which will allow you to optimize your time, improve your spray coverage and protect your precious crops.